Understanding Gas Mask Filters - Which One Is Right For You?

Posted by Civil Safety on 6th Mar 2023

We can survive three weeks without food, three days without water, but only three minutes without breathable air.

That's why protective gas masks can be a lifesaver in case of disasters like terrorist attacks or nuclear meltdown. But you might not realize that without the right filter, even the best gas mask is useless.

Because modern 40 mm gas masks filters are specialized to deal with any number of hundreds of toxins and airborne contaminants-ranging from chemical to biological, radiological and even nuclear-all while fitting the same gas mask.

A single filter can protect you from all of the contamination from a nuclear meltdown for forty full hours, while another filter could help you safely navigate the smoky environment of a house fire to reach safety.

But each gas mask filter has its limitations…

Each filter has a shelf life, classification, specs and price. The craftsmanship of their construction matters just as much as the science behind their effectiveness. Creating a working gas mask filter takes specialized knowledge of how to impregnate carbon with a key balance of metal salts and then treating the blend with chemicals to pass strict testing requirements.

These complicated factors are often overlooked by new and even experienced buyers. That’s a mistake that can cost you time and money…or something even more important.

So, we’re going to look at everything you need to know about protective gas masks filters: from their practical function and specifications to the logistics of storing them and, should the need arise, putting them to potentially life-saving use.

We’ve assembled all the research you need to make an informed decision and give your family the protection they might need.

Let’s get started…

GAS MASK FILTERS 101

The history of gas masks and how gas masks filters became practically universal is something we've already covered in our Gas Mask Buyer's Guide, so we won't delve into that here.

Modern protective gas masks filters, on the other hand, are truly a technological marvel.

It all starts with activated charcoal: a carbon filter media with an enormous surface area. There are approximately 130,000 square meters of surface area on just 100 grams of activated charcoal. It is carefully impregnated with a specific blend of metal salts and then treated and tested to ensure effectiveness.

Carbon impregnation is an exacting and skill-intensive process that takes years of mastery to consistently get right. Beyond the science, it takes a great deal of craftsmanship and knowledge to do it correctly. This special filter media is added to other layers with elements like microfiber filter paper that protects against dust and particulates.

The fiber density works as a fine mesh, reliably capturing the finest particles including aerosols, smoke, micro-organisms, and highly toxic particles. Particle, combined, special and NBC filters are equipped with special hydrophobic P3 class filter elements to ensure superior performance.

GAS MASK FILTER FUNCTION BASICS

Gas masks filters rely on three chemical processes to provide clean air in even the most toxic environments.

Filtration

is the most basic process, separating solid particles and aerosols from breathable air using media like charcoal.

Physical adsorption

happens when the captured substance condensates into the porous structure of the filter's activated carbon. This process actually captures gas molecules as they pass through, neutralizing threats.

Chemisorption

happens when physical adsorption meets the impregnated chemicals in a filter's activated carbon. During this process, even the most toxic elements can be momentarily captured, forced to interact with impregnated elements and immediately neutralized.

Due to the precise nature of filter construction and the mechanics involved, there are a few key classes of filters you'll notice immediately:

1. Particle filters

use basic filter media like Class 16 fiber paper to filter out common toxins. They're basic and affordable due to their simple construction. These are more often used for construction and demolition.

2. Gas filters

use the impregnated carbon we talked about above to provide more comprehensive protection from airborne threats. Note that these gas filters typically lack the mechanical filter media of particle filters.

3. Combined filters

are, as the name implies, a combination of gas and particle filters to provide more comprehensive protection from a wider variety of threats than either can provide alone.

4. Special filters

like most CBRN filters on the market today, take protection to an even higher level, with safeguards against things like organic substances with low boiling points, including mercury, COx, NOx and radioactive metal iodide.

To produce a modern gas mask filter takes unprecedented skill and expertise. Fortunately, it couldn’t be any easier to put one to use.

Gas masks filters are easy to carry, use and store, with a shelf life that can stretch into decades, and depending on the specific filter, they can provide up to 40 or more hours of practical protection from airborne contaminants and toxins. Any worthwhile gas mask filter will have these details laid out in the included documentation. This can make logistics straightforward, as you’ll see in the Storage & Shelf Life section below.

Many filters have the same round shape and size that you probably already know. Inside, each filter has a unique combination of chemical and mechanical media to filter out particulates and provide the user with breathable air even in extreme environments.

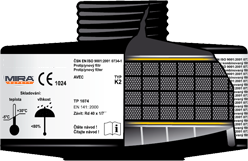

Due to the complicated nature of how these filters are built, there’s no “one size fits all” solution, so filters are classified based on the protection they provide—typically designated by a series of numbers and (sometimes) color-coded bands (per standard EN 14387+A1). More on that in Filter Classification below.

It’s important to note that these color-coding systems are primarily used for easy identification by industrial workers, so you won’t see them on all filters (they’re noticeably absent on the NBC-77 SOF filter, for example, which is all grey). Most (but not all) of the mask filters you’ll see on the market today are threaded to screw into gas masks with one of two popular formats known as 40 mm NATO and GOST.

As the name implies, 40 mm NATO is the filter standard used by NATO and US armed forces (conforming to the specifications of STANAG 4155 EN148-1), making these filters a popular and readily available choice for law enforcement, private military contractors and civilians.

For 99% of concerned civilians, 40 mm NATO filters are what you want. It’s an actively policed and maintained format that’s associated with a raft of other NATO gas mask filter requirements and regulations—so even if you’re paying a few bucks more, you know what you’re getting. We’ll cover a few of the best NATO filters for your money in our Popular Filter Choices section below.

GOST, on the other hand, is the competing Russian standard for gas masks and filters. Filters like the VK-450 can be GOST-certified while using the standard NATO 40mm threading, giving you a practical and budget-friendly alternative that still works with your favorite gas masks.

GOST testing is practically a copy of Europe’s CE testing, ensuring you get a solid product. It’s just important to steer clear of expired GOST filters or anything from the 80s and 90s. These older filters can contain chromium or asbestos, both of which can be seriously hazardous.

More on that in the Filters to Avoid section below.

Some newer mask filters (like those used with the M50) use a proprietary thread, meaning they’ll only work with a specific gas mask. This can provide some key advantages, but it can also limit your choice of filters—at a higher cost than civilian-ready CBRN masks and filters.

KEY THINGS TO REMEMBER ABOUT MASK FILTERS

- Gas masks & filters require at least 17% ambient oxygen levels (19.5% if in accordance with NIOSH) to function, any less requires a self-contained breathing apparatus (SCBA).

- The expected concentration of harmful substances in the air, with regard to the period of maximum possible use, should be 1,000 ppm (0.1% volume) for a Class 1 filter; 5,000 ppm (0.5% of volume) for a Class 2 filter; 10,000 ppm (1% of volume) for a Class 3 filter.

- If a gas mask filter is used against radioactive substances, mercury or other highly toxic substances, low-boiling organic substances, tear-producing and irritating substances, dangerous microorganisms, NOx or carbon monoxide, it cannot be reused!

- Always use a filter with the P3 or P3D filter element against solid and liquid particles, micro-organisms, viruses, smoke, etc.

- The maximum useful life of a filter against mercury vapors is legislatively defined by European standards as 50 hours.

- Mask filters cannot be cleaned so do not apply pressurized air or water.

As you can already see, there’s no shortage of choices when it comes to picking your gas mask and filter. If you feel overwhelmed, it can be helpful to take a step back and ask what you really need from your gas mask and filter setup. Will you use your gas mask filter on the job?

FILTER CLASSIFICATION

As mentioned above, canister mask filters offer versatile and reliable protection from hundreds of contaminants, toxins and particles. But these filters are still limited by practical concerns like size, weight and being porous enough for you to comfortably breathe through them.

That’s why individual filters are classified and coded according to a strict system, informing users of the specific types of toxins and compounds each filter can protect against.

You don’t necessarily have to memorize these classifications, but it’s important to keep them in mind when purchasing mask filters.

And beyond the basic classifications, there are a few deeper points to consider…

First is the level of particulate-filtering efficiency. This is a crucial consideration. After all, it’s not just about the contaminants in case of a disaster—there’s also going to be a great deal of dust and airborne debris. These particles can gradually accumulate inside the filter itself, reducing efficiency and increasing the chances you’ll be exposed.

Particle filter levels are currently defined by the EN143 standard to protect users against airborne dust, particles and liquid/solid aerosols. P1 level filters are less efficient, designed to stop at least 80% of airborne particles. P2 filters are designed to stop 94% of airborne particles, and P3 filters offer high efficiency, cutting off at least 99.95% of all airborne contaminants (all at 95 L/min airflow).

Particulate filtration is key to surviving many CBRN threats, which is why most modern CBRN filters offer P3 protection.

Another major factor to consider is the “reactor” classification. As mentioned above, this classification indicates the filter can prevent the intrusion of radioactive iodine often associated with nuclear fallout or post-meltdown exposure. True CBRN filters should almost always have this designation.

Filters may be labeled as either NBC filters (nuclear, biological, chemical) or CBRN filters (chemical, biological, radiological, nuclear). The former is generally considered an outdated term from the Cold War. Some of the most common NBC filters on the market today are old Israeli civilian filters which you’re best off avoiding.

In recent years, NBC filters evolved into CBRN to provide protection from radiological threats like dirty bombs, so you’re best off going for CBRN filters when possible.

FILTER CERTIFICATION

Of course, a filter’s classification is only as good as the agency that certifies it—and the standards to which it’s certified.

As mentioned above, the National Institute for Occupational Safety & Health (NIOSH) is a key certification body for American gas masks and filters. NIOSH certification can be prohibitively expensive for smaller companies though, so it typically comes at a premium in terms of cost to you, the consumer.

It’s important to note that NIOSH CBRN certification is given to the gas mask and filter as a unit. So switching to a different filter or a newer gas mask may in some cases be a step away from the NIOSH standard.

And that’s the key with NIOSH; it’s an optional certification unless your gas mask is part of your occupational equipment. You can get a great non-NIOSH gas mask and filter.

Europe’s “CE” is an equally strict standard. The difference is that while non-NIOSH masks can be sold in the US, non-CE masks cannot be sold anywhere in the European Union.

As we’ve covered above, GOST is a Russian standard that closely mirrors CE. GOST also has its own threading standard, so if you are considering GOST-approved filters, make sure they’re compatible with your gas mask.

But what’s the right filter for your needs?

If so, and you’re in the private sector, you’ll likely need a more expensive NIOSH-approved setup (more on that in a moment). State and federal jobs aren’t regulated by NIOSH standards, which gives you more options. Instead, if you’re just trying to prepare for the worst, you can get a reliable NATO standard gas mask and filters for a lower price. Preparing for specific use cases can make your purchases more effective.

But first and foremost, you need to know what it is that you’re purchasing. So let’s take a look at how filters are classified and defined.